At DOLLE, we have taken an exciting step towards automation by implementing a collaborative robot (cobot) in our production. This new technology has provided us with valuable experiences that we would like to share with other companies considering the use of robots in their own processes.

As Production Manager Steen Laier explains, we see great potential in cobots. Instead of allowing robots to take over the entire production process, we have found that it can be both economical and practical to have a robot handle the majority of the work while our employees manage the remaining tasks.

"Robots tasked with performing all duties can quickly become costly—especially if flexibility is needed in the process. By having the robot take care of 80% of the task and our employees the last 20%, we not only achieve time savings but also improve the working environment," says Steen Laier.

Watch the interview with DOLLE's Production Manager Steen Laier, uploaded on the Technological Institute's YouTube channel.

Efficiency and Improved Working Environment

We have experienced that cobots can make a significant difference for our employees' well-being. Many of the manual tasks in our production can be physically demanding, especially when performed day after day. By allowing the robot to handle some of the more strenuous tasks, we reduce the risk of work-related injuries and thereby improve the working environment.

A Learning Process Rather than Quick Financial Gain

When we implemented our first collaborative robot, the goal was not to achieve a quick financial gain. Instead, we viewed it as a learning process. The purpose was to explore how the robot could create value in our production and where it could make a difference.

"We have chosen to see the first robot as a learning robot. It hasn't been crucial for it to have a payback period of one, two, or three years. Instead, we have focused on learning how we can work with the technology and where it can inspire us for further optimization," explains Steen Laier. In fact, it has become evident that more employees now see the potential in using the robot in their respective areas of production.

Challenges with Programming

Although the cobot has provided us with new opportunities, there have also been challenges along the way. We decided early on that we would learn to program the robot ourselves to build internal knowledge of the technology. However, this decision has proven to be more time-consuming than we initially expected.

"It has taken longer to learn how to program the robot than we had anticipated. We received some programming from our supplier but wanted to build on it ourselves to gain a greater understanding of the technology," says Laier.

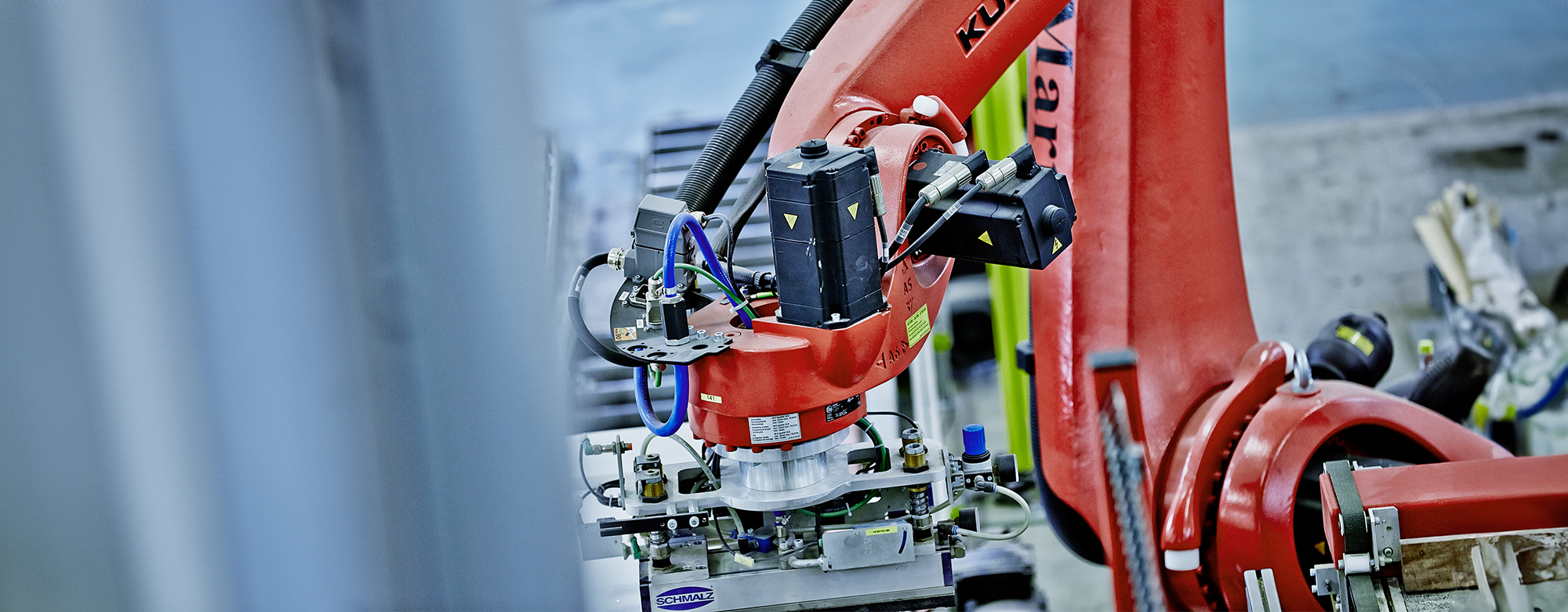

The robot is currently functioning primarily as a handling robot, which can be moved around to different areas in production. To utilize it even better in the future, we have decided to offer courses to our employees in programming so they can use the robot more effectively in various processes.

Our Advice to Companies Considering Cobots

If you are considering implementing collaborative robots in your production, our advice is to be open to the challenges and not hesitate to take the leap. However, it is important to have realistic expectations and ensure that you invest the necessary resources.

"A cobot is not a plug-and-play solution. It requires a clear plan for where and how the robot will be used, as well as a thorough evaluation of whether it is a cost-effective solution," concludes Steen Laier.

At DOLLE, we have already experienced the benefits of adopting robot technology. We look forward to harnessing its full potential and continuing to improve both our efficiency and working environment through innovative solutions.